As all major carriers are trying to increase dry cargo rates, they find comfort in the fact that reefer cargo continues to be high-paying cargo, and even though the operational costs are high, reefer cargo remains very profitable. But what does one need to know in order to participate in this complex business?

Here are some simple rules for all the maritime hopefuls out there, which can help you and your team better understand some aspects of the reefer world:

Rule #1: Reefer containers are pre-tripped before being delivered to the customer for stuffing, meaning that they should have been configured to the desired settings that the shipper requested beforehand – e.g. temperature, ventilation, humidity, etc. (COST)

Rule #2: Reefer containers are steam-cleaned before being delivered to the customer. The boxes should be odor-free from previous shipments, and clean to receive the new commodity. (COST)

Rule #3: Reefer containers must be always plugged-in. On the road, they must be plugged-in to the gen-sets (clip-ons or underslung.) At the terminal, they must be plugged-in on the terminal power pack. On the vessel, they must be plugged into the vessel power pack. Therefore, electricity is a huge cost that needs to be considered. (COST)

Rule #4: Reefer containers are not just for carrying perishable cargo. All kind of commodities that need to be transported in a temperature-controlled environment are considered reefer cargo. They could include antique furniture, works of art, chemicals, hides, etc.

Rule #5: Reefer rates, as dry rates, are not all the same. Frozen cargo rates are generally much cheaper than chilled rates. The rule is that the more likely a commodity is to be damaged due to a potential fluctuation in the temperature, the higher the rate increase (e.g. ice cream.) Rates are also determined by the commercial value of the cargo. Pharmaceuticals are usually the most-expensive commodity, while frozen poultry is considered the “waste paper” for reefer cargo.

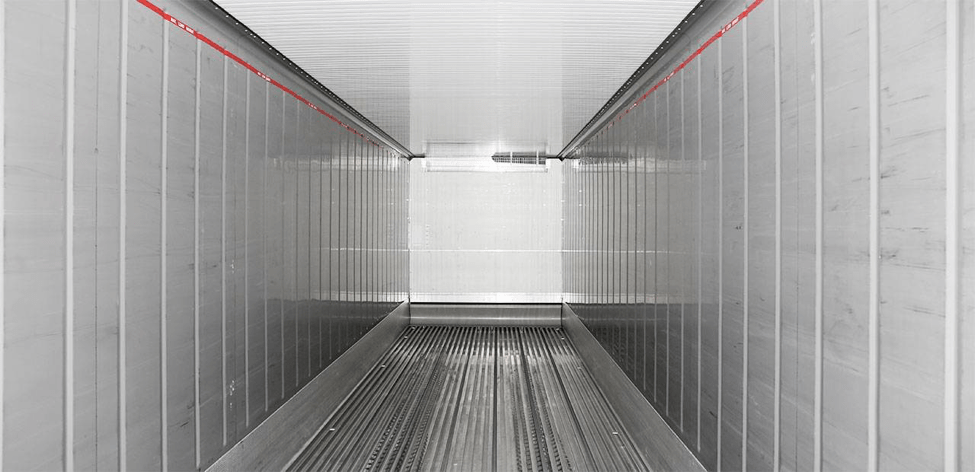

Rule #6: The cargo must be loaded in the reefer container in such a way that continued air flow is allowed. If you try to load more cargo than you should, you may find the cargo damaged at the receiving end, because cold air was being blocked. In addition, packing is important, since special boxes with holes are needed for chilled goods, and closed boxes with plastic wrapping are required for frozen cargo.

Rule #7: What is the shelf life of the cargo? You need to know the length of time in which the cargo remains fit for consumption. You must also know the varieties of a commodity. For instance, certain varieties of apples have a shorter shelf life than others. As such, you need to choose the correct service to load the cargo depending on the T/T.

Rule #8: Seasonality is also very important. You must know when the crops are coming up, or becoming available, in order to go after the cargo. Climate change can also impact the crop or catch (in the case of fish and seafood.)

Rule #9: New technologies are being introduced to reduce the ripening process of perishable goods. Ethylene is the hormone responsible for that, while manufacturers are trying to find ways to slow the production down. This will also allow steamship lines to participate in carrying traditional air freight commodities, like fresh flowers.

Rule #10: All commodities do not require the same treatment. Some commodities need a fluctuation of the temperature in-transit, while others need cold treatment in-transit. Some countries also have strict requirements in downloading data from the reefer container, and besides the general log that shows any alerts and discrepancies, they may require probes (a type of thermometer) to be installed in the container.

The list is endless since every commodity needs different treatment, but hopefully these 10 simple rules gives you a better understanding for the transportation of reefer cargo.

- 168shares

- 56Facebook

- 79LinkedIn