COVID-19 has had an unprecedented effect on logistics and the overall supply chain.

When I wrote my previous article on coronavirus’s effects on shipping, COVID-19 was still a local issue limited mainly to China, and there were not yet global concerns about the virus. At the time, the expectation was that once China returned to work and the virus subsided, an overall improvement on logistics and the supply chain would follow.

Today, the reality is entirely different.

There is not a major import country that the virus has not affected. U.S. purchase orders are slowing down as COVID-19 now affects almost all countries in Asia, from India, Malaysia, Bangladesh, and Pakistan to the Philippines and others. In China, a second wave of infections has started, causing more concerns. There are major lockdowns and closures worldwide, causing tremendous challenges for logistics and the overall supply chain.

At the beginning of March, the overall picture and outlook for global trade was very different. China began returning to work and production restarted slowly. Many U.S. importers were looking to accelerate their orders and shipments. Many importers had back orders from the pre-Chinese New Year period that were starting to be shipped.

Overall, inbound March cargo TEU volume has been strong. However, from the second week of the month, there has been a slowdown, cancellations, and postponements as the number of COVID-19 cases has exploded in the U.S. and around the world.

Many importers put a hold on existing purchase orders, changing between two weeks and two months.

We observe that retail and discretionary merchandise, fast fashion items, toys, and electronics, are especially being affected negatively from the coronavirus situation. At the same time, importers that bring in raw materials or complementary products for other businesses, business-to-business companies, and medical supply companies are still in OK shape in terms of shipments. There is a surge of shipment inquiries for essential products such as sanitizers, face masks, and medical gloves.

At MTS Logistics, we are also observing major cancellations from national big box retailers, which most importers supply, for orders that already arrived to U.S. ports, causing storage challenges for importers, ports, and storage facilities in general.

Another pressure on ports is that since all nonessential businesses are ordered closed, pick-up and delivery of many containers from ports are in limbo. Soon, this will cause tremendous problems with demurrage and detention charges, which might push some ports to declare a force majeure event (as some ports in India already did.)

For ocean carriers, there was great hope amongst most of them about two weeks ago. Some already had opened negotiations for the contracts for 2020-2021 contract season. Immediately after holds and postponement requests from importers that work with RFQs, we also observed some carriers postponed final rate negotiations to May. Direct BCO negotiations are underway, but when they will be finalized is unclear.

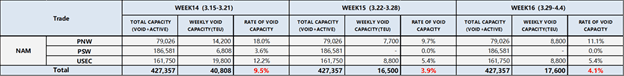

Another major shift is the blank sailing program that is imposed by carriers with the hopes of keeping rate levels at certain levels, prior to contracts being finalized, and managing diminishing demand from U.S. importers. Major capacity cuts and service cancellations are underway. I am sharing the latest blank sailing program as below.

Blank Sailings:

Blank sailings mean less equipment and service offerings for U.S. exports. At this point, it is certain that April will be a pretty challenging month for imports. However, a quick turnaround on volumes is on the horizon.

As early as mid-May, we may see shipments that are being delayed being rebooked with full recovery in June onwards expected with back-to-school and Christmas shipments. The situation is very fluid at the moment, but a V-shape recovery with shipment numbers is on the horizon. These are very challenging times for small-to-mid-size importers and for all stakeholders in the logistics industry.