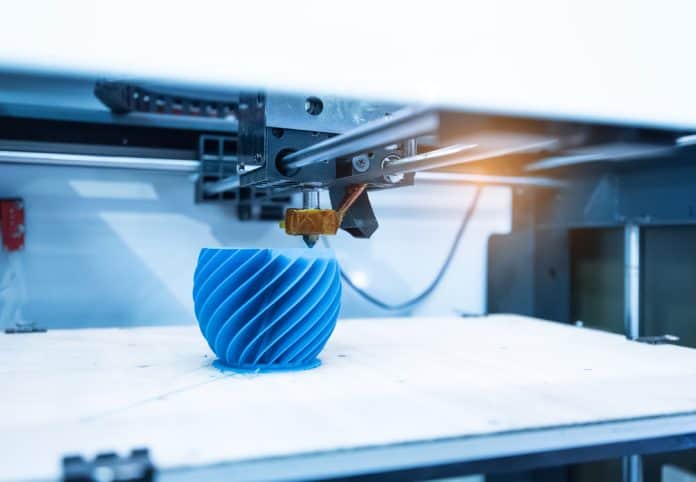

3D printing, a type of additive manufacturing, is a massive innovation which will have a large and long-lasting impact on global supply chains and operations.

The 3D printing process creates physical objects through the “printing” or adding of many small, thin layers of material, which combine to form the 3D object while reducing waste. Right now, 3D printing is mostly used for prototyping and limited production runs. Soon, further innovations in 3D printing will mean the technology gets rolled out on a larger, industrial scale. When that happens, new opportunities will open for the world of logistics, including more efficient delivery solutions and raw material production.

Why is 3D printing likely to transform commerce and the supply chain?

Even as it is largely still in its early years, the 3D printing market is worth almost $13 billion globally. By next year, the industry will grow by as much as 17%. With growth at such a high level, as well as the introduction of 3D printing to replace traditional manufacturing in some sectors means that the supply chain will likely see huge effects.

Some potential benefits of 3D printing on the supply chain include:

- Reduced costs overall, as manufacturing becomes cheaper and more efficient.

- Reduced trade barriers including resistance to tariffs, etc. as materials can be produced at home versus abroad more often.

- Improved customer service, as companies can re-allocate budgets from savings.

- Reduced carbon footprints as all of the factors above weigh on more efficiency.

- More innovation, as manufacturing can be performed quicker and easier.

How does 3D printing offer companies more options to meet supply chain challenges and slowdowns?

With traditional manufacturing, factories are set in one place and are a fixed infrastructure. Over the past several decades, many U.S. companies moved manufacturing overseas for cost-cutting reasons. Now, with global geopolitical turmoil as a result of the Covid pandemic, supply chain woes, the Russia-Ukraine conflict, etc., companies who ship goods globally are experiencing many shortfalls and disruptions.

With 3D printing, however, companies can produce many components for their products in their home country rather than overseas, as manufacturing becomes more efficient and costs go down with 3D printers. This flexibility gives manufacturers a way out of supply chain issues that are occurring globally. Additionally, goods can be easily customized for a particular customer’s needs, allowing for efficiency and waste-cutting. As a result, supply chains will become smarter, more flexible, agile, and more.

In short, 3D printing will bring a new level of innovation and efficiency to the supply chain.

As 3D printing technology is improved and rolled out on a greater scale, less moving parts will be required to produce a particular product. In turn, manufacturing and the supply chain will become simpler, costs will decrease, lead times will decrease, and in general, manufacturing will become easier. Customized manufacturing will become much easier.

And, as we all learned is super important after the supply chain woes of the past two and a half years, resistance to geopolitical tensions and global slowdowns will be feasible for the first time as an alternative to globalization emerges. Since 3D printing is also more environmentally-friendly, companies looking to reduce their overall carbon footprint may find it more attractive, too.